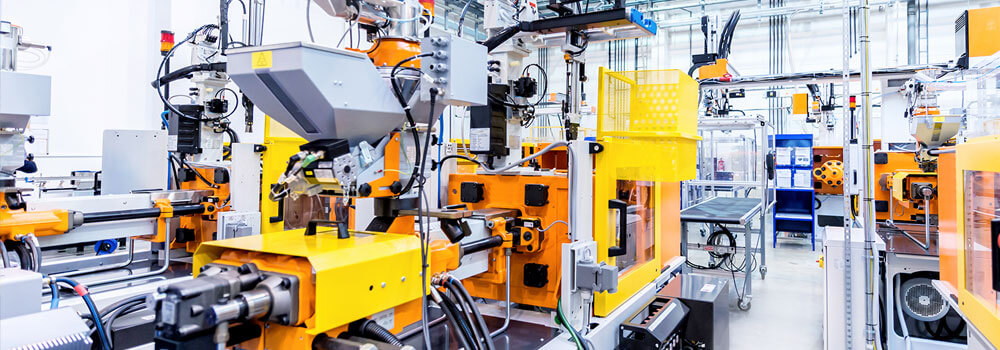

Michigan has long been a hub for industrial manufacturing, with a strong reputation in the automotive, aerospace, and medical sectors. Injection molding companies in Michigan play a crucial role in supplying high-quality plastic components for various industries, ensuring the production of durable, cost-effective, and precision-engineered products. The state’s well-developed manufacturing infrastructure, combined with access to skilled labor and cutting-edge technology, makes it an ideal location for plastic injection molding. Companies in Michigan leverage automated systems, robotics, and real-time quality monitoring to enhance production efficiency while minimizing costs and material waste. The ability to produce high-volume, intricately designed plastic components with consistent accuracy has made injection molding a preferred method for manufacturers across multiple industries.

Another advantage Michigan offers is its strategic location, which provides seamless access to raw materials and a well-connected logistics network. This accessibility enables manufacturers to source materials efficiently and distribute finished products to national and international markets with minimal delays. Additionally, Michigan’s injection molding companies are increasingly incorporating sustainable practices, such as using recyclable plastics and energy-efficient manufacturing techniques, to reduce their environmental impact. As global demand for eco-friendly and lightweight materials continues to grow, Michigan’s injection molding industry remains at the forefront of innovation, adapting to evolving market needs and technological advancements.

Industries That Rely on Injection Molding in Michigan

Automotive Industry

Michigan is synonymous with the automotive industry, being home to major car manufacturers and an extensive network of suppliers. The automotive sector relies heavily on injection molding to produce lightweight, durable plastic components that enhance vehicle performance, fuel efficiency, and safety. From interior panels and dashboard components to exterior trims, fuel system parts, and under-the-hood components, injection-molded plastics are essential in modern vehicle manufacturing. The ability to produce complex geometries with tight tolerances ensures that these parts fit seamlessly within the overall vehicle design.

In addition to traditional plastic molding, Michigan’s injection molding companies are actively developing advanced materials, including reinforced plastics and composite blends, to meet the increasing demand for high-performance automotive components. Many manufacturers are also integrating overmolding and insert molding techniques to enhance product durability, reduce assembly costs, and improve component aesthetics. With the rise of electric vehicles (EVs) and autonomous driving technologies, the need for lightweight, high-strength plastic components will continue to grow, further solidifying Michigan’s role as a leader in automotive injection molding.

Medical and Healthcare Sector

The medical and healthcare industry depends on precision and quality, making injection molding a critical process for producing sterile, high-performance medical components. Injection molding companies in Michigan specialize in manufacturing a wide range of plastic medical products, including surgical instruments, syringes, IV components, diagnostic device housings, and implantable medical devices. The ability to create small, intricate, and biocompatible plastic parts with tight tolerances is essential in medical applications, where precision can impact patient safety and treatment outcomes.

Michigan-based injection molding companies adhere to strict regulatory standards, including ISO 13485 certification for medical device manufacturing, to ensure compliance with industry requirements. Many manufacturers also employ cleanroom molding processes to maintain contamination-free production environments. With continuous advancements in medical technology and the growing demand for disposable and reusable medical devices, the injection molding industry in Michigan is well-positioned to support the evolving needs of healthcare providers and medical equipment manufacturers.

Aerospace and Defense

The aerospace and defense industries require high-performance, lightweight materials that can withstand extreme temperatures, pressures, and environmental conditions. Injection molding has become a preferred manufacturing method for producing aerospace-grade plastic components due to its ability to create durable, lightweight, and precisely engineered parts. Michigan’s aerospace injection molding companies manufacture components such as interior panels, insulation systems, fluid handling systems, and structural reinforcements used in aircraft and defense applications.

Injection-molded plastics offer several advantages in aerospace manufacturing, including weight reduction, corrosion resistance, and cost savings compared to traditional metal components. Michigan-based injection molding companies work closely with aerospace engineers to develop custom plastic solutions that meet stringent performance and safety standards. The industry is also seeing increased adoption of advanced polymers, such as high-temperature-resistant plastics and carbon fiber-reinforced composites, to improve the performance and longevity of aerospace components.

Consumer Goods and Packaging

Injection-molded plastics are widely used in the consumer goods and packaging industries, where manufacturers require durable, visually appealing, and cost-effective products. Michigan’s injection molding companies produce a diverse range of consumer items, including electronic enclosures, household appliances, kitchenware, and personal care product packaging. The ability to mass-produce high-quality plastic components with consistent precision makes injection molding an essential process for meeting consumer demand.

The packaging industry also heavily relies on injection molding to produce plastic containers, caps, closures, and custom packaging solutions. Many Michigan-based manufacturers are incorporating sustainable practices by using biodegradable and recyclable plastics to reduce environmental impact. Additionally, the development of innovative packaging designs, such as tamper-evident closures and lightweight yet durable plastic containers, continues to drive growth in the sector. As consumer preferences shift toward sustainable and functional packaging, injection molding companies in Michigan are adapting their production techniques to align with these trends.

Choosing the Right Injection Molding Company in Michigan

Selecting the right injection molding company is crucial for businesses looking to produce high-quality plastic parts efficiently and cost-effectively. Michigan offers a wide range of injection molding providers, each with varying capabilities and expertise. Businesses should consider several factors when choosing a manufacturer, including production capabilities, material selection, quality assurance, and lead times.

A reputable injection molding company should offer expertise in various molding techniques, including multi-shot molding, insert molding, and overmolding. These advanced processes enable manufacturers to create complex, multi-material components that enhance product performance and durability. Additionally, the company should have experience working with a broad range of plastics, such as ABS, polycarbonate, polypropylene, and engineering-grade resins, to meet the specific needs of different industries.

Quality assurance is another critical factor to consider. Michigan’s top injection molding companies implement rigorous quality control processes, including dimensional inspections, material testing, and part validation procedures. Certifications such as ISO 9001 and IATF 16949 (for automotive applications) demonstrate a company’s commitment to maintaining high manufacturing standards. Businesses should also assess the manufacturer’s production efficiency and ability to meet tight deadlines. A well-organized supply chain and efficient manufacturing processes help minimize production delays and reduce costs.

Future Trends in Michigan’s Injection Molding Industry

The injection molding industry in Michigan is evolving rapidly, with advancements in automation, material science, and sustainable manufacturing practices shaping its future. The adoption of Industry 4.0 technologies, such as artificial intelligence, machine learning, and real-time data monitoring, is improving production efficiency and quality control. Smart injection molding systems can detect defects, optimize cycle times, and reduce waste, making the manufacturing process more cost-effective and sustainable.

Sustainability is another key focus area, with many Michigan-based injection molding companies investing in biodegradable and recycled plastics. As environmental regulations become stricter and consumer demand for eco-friendly products increases, manufacturers are shifting toward greener alternatives. The development of bio-based resins and energy-efficient molding processes is helping companies reduce their carbon footprint while maintaining high production standards.

Additionally, Michigan’s injection molding companies are expanding their capabilities to cater to emerging markets, such as electric vehicles (EVs), medical wearables, and smart home devices. The need for lightweight, high-strength plastic components in these industries is driving innovation in material selection and molding techniques. Collaborations between injection molding companies and material scientists are leading to the development of new polymer blends with enhanced performance characteristics.

Injection molding companies in Michigan play a vital role in the state’s manufacturing ecosystem, supplying high-quality plastic components to a diverse range of industries. With advanced molding technologies, a skilled workforce, and a commitment to innovation, Michigan remains a leader in the injection molding sector. As industries continue to demand precision, efficiency, and sustainability, Michigan’s injection molding companies are well-positioned to meet these evolving challenges. Whether for automotive, medical, aerospace, or consumer goods applications, businesses can rely on Michigan’s injection molding industry to deliver cost-effective and high-performance plastic solutions, including expertise in Injection mold China for global manufacturing needs.

The Competitive Edge of Michigan’s Injection Molding Industry

Michigan’s injection molding industry is a crucial player in the U.S. manufacturing sector, providing plastic components to diverse industries. With the state’s extensive industrial infrastructure, skilled workforce, and proximity to major markets, Michigan-based injection molding companies have a competitive edge over competitors in other regions. Many companies specialize in high-volume production, offering cost-effective solutions without compromising quality. Advanced automation, robotics, and smart manufacturing technologies allow manufacturers to reduce labor costs while maintaining precision and consistency.

Another factor that sets Michigan apart is its strong supply chain network. The state is home to numerous raw material suppliers, tool and die manufacturers, and logistics companies, making it easier for injection molders to access resources and distribute products efficiently. This streamlined supply chain reduces lead times and enables manufacturers to offer faster turnaround times for their customers. Additionally, Michigan-based companies are investing in research and development (R&D) to create new polymer blends, enhance material performance, and explore sustainable alternatives that meet the growing demand for eco-friendly plastic products.

The Role of Custom Injection Molding in Michigan

Custom injection molding is a significant service offered by many Michigan-based injection molding companies. Businesses across various industries require unique plastic parts tailored to their specific needs, and custom molding provides the flexibility to create highly specialized components with precise dimensions and material properties. Custom injection molding services often include design consultation, prototyping, mold fabrication, and final production, ensuring that each product meets stringent quality standards.

The automotive sector, in particular, benefits from custom molding, as many vehicle components require complex geometries and high durability. Custom injection molding also plays a critical role in the medical field, where precision and biocompatibility are essential. Michigan’s injection molders work closely with medical device manufacturers to develop specialized plastic parts for surgical instruments, diagnostic equipment, and wearable medical devices.

Additionally, consumer electronics manufacturers rely on custom molding to create enclosures, housings, and intricate plastic parts for devices such as smartphones, gaming consoles, and home appliances. With advancements in 3D printing and computer-aided design (CAD), Michigan’s injection molding companies can quickly develop prototypes and refine product designs before mass production, reducing development time and costs.

Michigan’s Injection Molding Workforce and Training Programs

A skilled workforce is one of Michigan’s greatest assets in the injection molding industry. The state boasts a large pool of experienced engineers, technicians, and machine operators who specialize in plastic injection molding processes. Many workers have extensive experience in mold design, material selection, and process optimization, ensuring that Michigan-based manufacturers can deliver high-quality plastic components.

To maintain a steady supply of skilled professionals, Michigan invests heavily in workforce development and training programs. Several technical colleges and universities offer specialized courses in plastics engineering, mold design, and manufacturing technology. Apprenticeship programs also provide hands-on training, allowing individuals to gain practical experience while working with experienced professionals.

Moreover, injection molding companies in Michigan collaborate with industry associations and research institutions to stay updated on the latest technological advancements. Continuous training programs help employees improve their skills in areas such as automation, robotics, and advanced material processing. By fostering a highly skilled workforce, Michigan ensures that its injection molding industry remains competitive in the global market.

Sustainable Injection Molding Practices in Michigan

Sustainability is a growing concern in the injection molding industry, and Michigan-based companies are taking proactive steps to reduce their environmental impact. Many manufacturers are incorporating energy-efficient machinery, biodegradable plastics, and recycling programs to promote eco-friendly production.

One of the key sustainability initiatives in Michigan’s injection molding sector is the use of post-consumer recycled (PCR) plastics. By repurposing plastic waste into new products, manufacturers can reduce landfill waste and minimize the environmental footprint of plastic production. Additionally, some companies are exploring bio-based resins derived from renewable sources, such as cornstarch and soy-based polymers.

Another important aspect of sustainability is energy efficiency. Michigan’s injection molding facilities are upgrading to all-electric and hybrid injection molding machines, which consume less energy compared to traditional hydraulic presses. These energy-efficient machines not only reduce electricity costs but also lower carbon emissions, making them a sustainable choice for large-scale plastic manufacturing.

Water conservation is also a priority for Michigan’s injection molding companies. Many manufacturers implement closed-loop water cooling systems to reduce water consumption and improve process efficiency. These systems recycle and reuse water, minimizing waste while maintaining optimal production conditions.

Technological Advancements in Michigan’s Injection Molding Industry

Michigan’s injection molding industry is at the forefront of technological advancements, continuously evolving to improve efficiency, precision, and product quality. Several key innovations are driving the industry forward, including automation, real-time quality monitoring, and advanced molding techniques.

Automation and Robotics

Automation has revolutionized the injection molding industry by enhancing productivity and reducing labor costs. Michigan’s injection molding companies use robotic systems to automate part handling, quality inspection, and assembly processes. Automated machines can operate 24/7, significantly increasing production output while maintaining consistent quality. Additionally, collaborative robots (cobots) work alongside human operators to streamline operations and improve workplace safety.

Real-Time Quality Monitoring

To ensure high-quality production, Michigan-based injection molders are implementing real-time quality monitoring systems. These systems use sensors and artificial intelligence (AI) to detect defects, measure dimensional accuracy, and optimize process parameters. By identifying issues early in the production cycle, manufacturers can minimize waste and reduce the likelihood of defective parts reaching customers.

Advanced Molding Techniques

Michigan’s injection molding industry is adopting advanced molding techniques to enhance product performance and design flexibility. Some of the most widely used methods include:

- Overmolding: Used to combine multiple materials into a single component, improving grip, durability, and aesthetic appeal.

- Insert Molding: Embeds metal or electronic components within plastic parts, reducing assembly time and improving structural integrity.

- Gas-Assisted Injection Molding: Creates hollow sections in plastic parts, reducing weight and material consumption without sacrificing strength.

- Multi-Shot Molding: Produces multi-colored or multi-material components in a single molding cycle, eliminating the need for additional assembly steps.

Global Impact of Michigan’s Injection Molding Industry

Michigan’s injection molding companies not only serve domestic markets but also have a significant global impact. Many manufacturers export plastic components to international clients, including those in the automotive, medical, and consumer goods industries. The state’s well-connected transportation infrastructure—comprising highways, railways, and international ports—facilitates efficient distribution to global markets.

Additionally, Michigan-based injection molders often collaborate with overseas partners to expand their reach. For instance, companies seeking cost-effective tooling solutions frequently work with suppliers specializing in Injection mold China, leveraging China’s expertise in high-quality mold manufacturing. This collaboration allows Michigan manufacturers to access competitively priced molds while maintaining superior production quality in their U.S.-based facilities.

Conclusion

Injection molding companies in Michigan play a vital role in the state’s economy and manufacturing sector, providing high-quality plastic components for a wide range of industries. With advanced technology, a skilled workforce, and a commitment to sustainability, Michigan remains a leader in injection molding innovation. As the industry continues to evolve, companies are embracing automation, real-time quality monitoring, and environmentally friendly practices to enhance efficiency and meet global demand.

Whether serving the automotive, medical, aerospace, or consumer goods industries, Michigan’s injection molding companies are well-positioned for future growth. By leveraging advanced manufacturing techniques and maintaining strong international partnerships, Michigan’s injection molders will continue to shape the future of plastic manufacturing.